Partica LA-960V2

Laser Scattering Particle Size Distribution Analyzer

The LA-960V2 combines the most popular modern sizing technique, Mie Scattering (laser diffraction) with state of the art refinements to measure particle size of suspensions or dry powder, measuring 10 nanometres to 5 millimetres.

Its method expert software makes it easy to create a robust, powerful method for research and development purposes as well as quality control. The flexible sample handling, robust platform, and wide size range ensure the LA-960V2 will handle the most extreme demands.

Key Features:

- Advanced Detector Design: The number of detectors, angular range, and layout each contributes to overall system performance.

- Superior Instrument-to-Instrument Precision: To provide the same experience regardless of manufacture date, operator skill, or geographic location. Achieve unmatched instrument agreement without the hassle of correlation.

- Automatic Laser Alignment in Seconds: Always make perfect measurements with computer-controlled laser alignment. The alignment process is finished in only a few seconds with HORIBA’s innovative approach.

- Guaranteed Accuracy and Precision: The LA-960V2 is a highly refined particle size analyzer capable of accurately measuring NIST-traceable size standards within 0.6% of the specification. Fully compliant with ISO 13320 recommendations regarding the measurement of materials on the D10, D50, and D90

- State of the Art Sampling Systems

Wet Measurement (Sample-to-sample analysis in less than 60 seconds)

The HORIBA LA-960V2 wet circulation system is an easy, fast, and very powerful dispersion system. The standard wet system offers a full package of a dispersant fill pump, liquid level sensor, circulation pump, 30 W in-line ultrasonic probe, and drain valve, which is all software-controlled for true one-button operation. This advanced design provides highly reproducible particle size results.

Dry Measurement (Automated, powerful dry-powder dispersion)

The LA-960V2 PowderJet combines several unique and patented features to provide the most reproducible dry measurements. Use the Auto Measurement function to control vacuum, air pressure, powder flow, start/stop conditions, measurement duration, and data processing. Designed to handle every application including small sample amounts, friable powders, and highly agglomerated materials.

- Smart Scans – Trigger function

This function allows for very precious materials to be measured accurately. When the sample amount is limited or low flowability, the Trigger functions perfectly to start and stop the measurement. - Self-Adjusting Powder Flow

Historically, the biggest challenge in dry powder measurement involved establishing an even powder flow. The LA-960V2 PowderJet has solved that challenge with a self-adjusting feedback loop to maintain a constant laser transmittance. This is a crucial factor in creating reliable, reproducible dry powder size measurements.

Applications:

- CMP slurry

- Catalysts

- Ink / Pigments

- Plastics

- Minerals

- Metal powder

- Emulsion

- Battery

- 3D printing

- Paper Coating

- Pharmaceutical

- Cosmetics

- Food / Drink

- Building materials

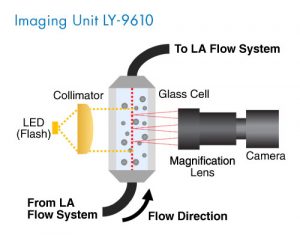

LY-9610 Imaging Unit

The imaging unit allows real-time observation, particle image acquisition, and assessment of the particles in the wet circulation system. It is small and integrated in the main unit without increasing instrument footprint!

Features and Benefits:

• Identify trace amounts of large particle contaminants or aggregates.

• Bubble detection.

• Improve your methods by developing an intuitive understanding of the effect of stirring, sonication, surfactant addition, etc.

• Detect large particles automatically.

• Shape distribution data (aspect ratio, circularity, length, width)*.

• Detailed analysis of captured images.

• Monitor trends in size and shape with trend graph and histogram.

Enquiry about Partica LA-960V2